Machine Vision Helps Intelligent Manufacturing, Shenzhen Huishi Releases Smrobot 3000 Series

How to deal with the pain points of shoe industry

With the rapid rise in labor costs, China Shoe industry Facing severe challenges, on the one hand, the shoemaking industry is moving to low-cost Southeast Asian countries; on the other hand, facing the replacement of industry 4.0 machines, the shoemaking industry is also returning to developed countries in Europe and America. In order to effectively deal with the bottleneck of industrial development and continue to grow stronger, it is imperative to upgrade the footwear industry.

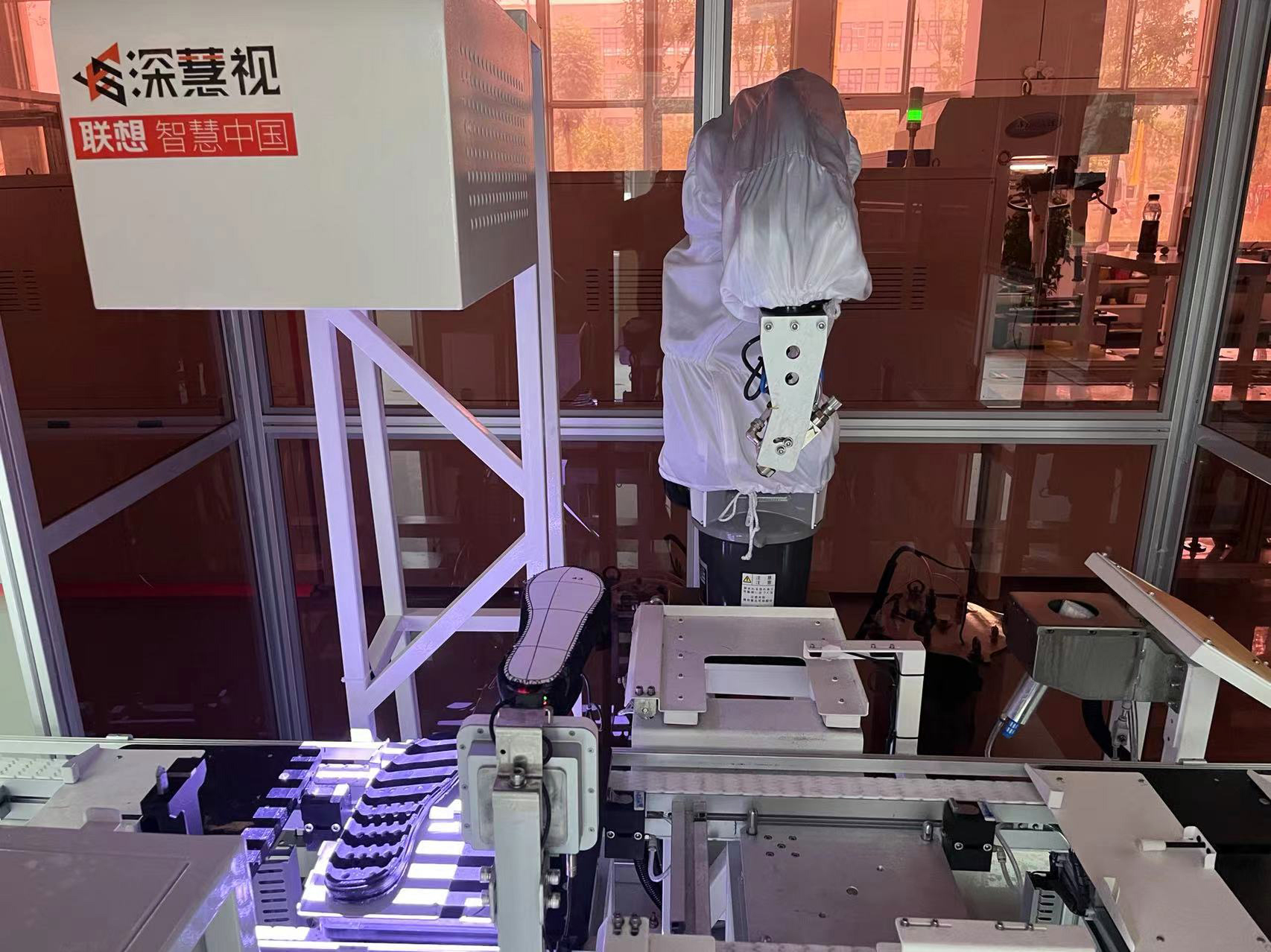

In view of the technical difficulties in realizing automatic manufacturing in flexible manufacturing, such as complex shoe type, innovative style and changeable materials in shoe industry, Shenzhen Huishi focuses on the independent and original 3D machine vision, which is suitable for Shoe industry 3D machine vision software and hardware innovation.

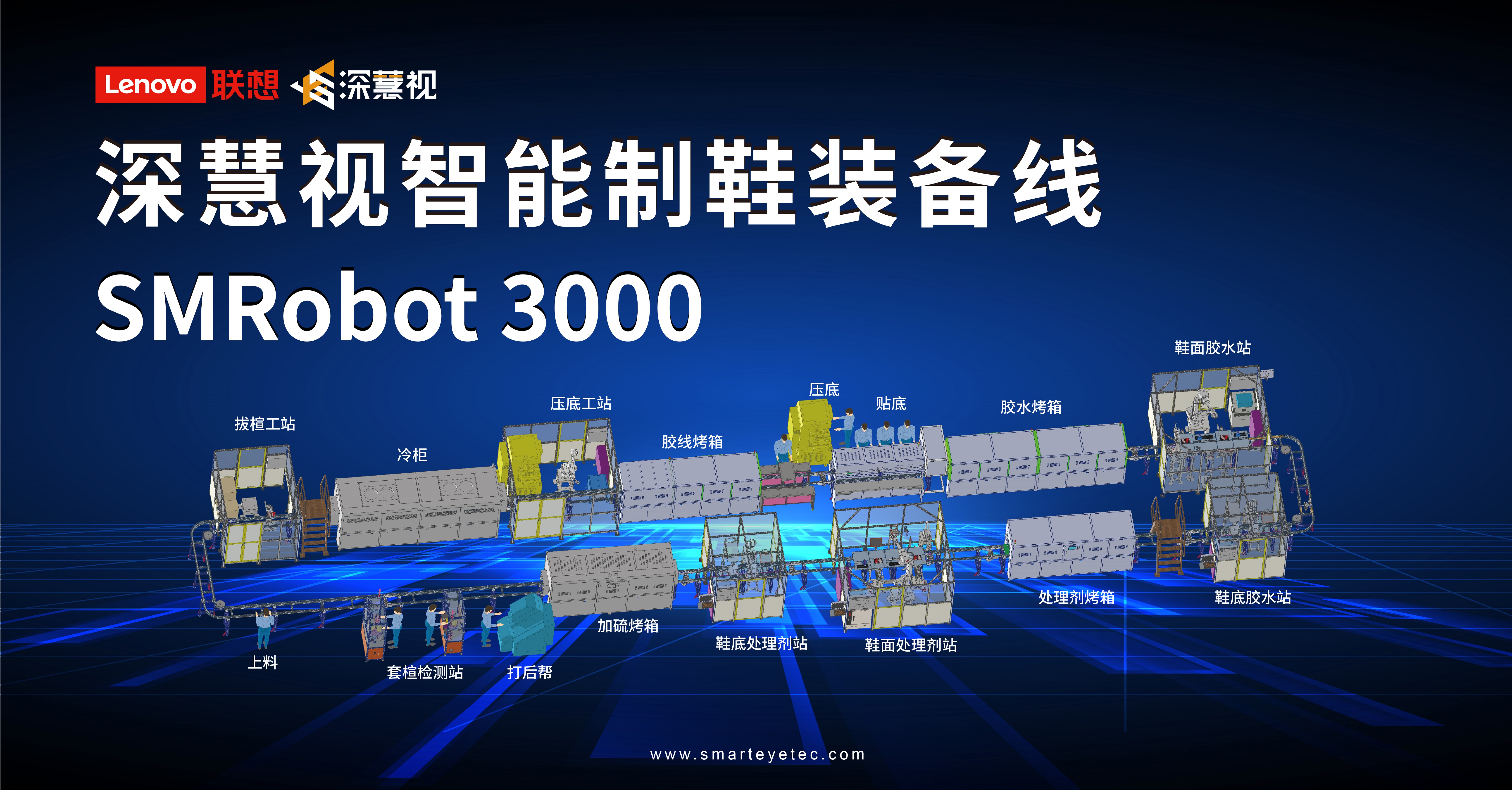

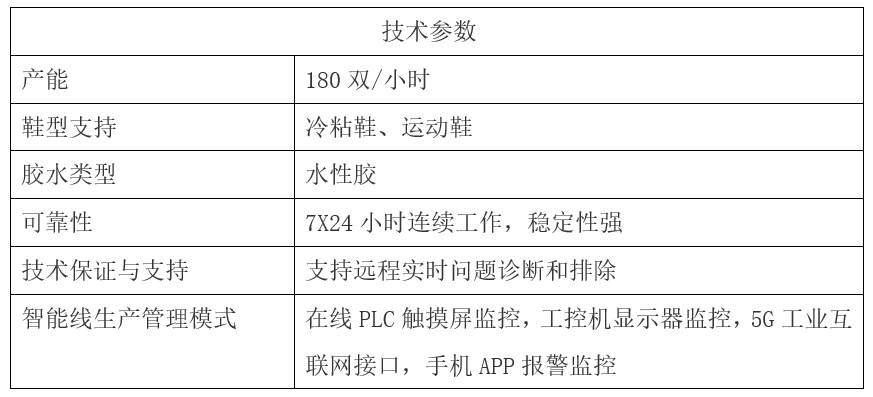

Technical indicators of smrobot3000

After years of independent research and development and deep grinding, Shenzhen Huishi has continuously upgraded its products and successfully developed the third generation Intelligent shoe making Line (smrobot 3000), has completed the batch production verification, has been unanimously recognized by customers. This product release of Shenzhen Huishi smrobot3000 series, a total of smrobot3180, smrobot3120 two models.

Customer value and economic benefit

Machine replacement The labor cost of the whole production line can be reduced by 30, which is 70% less than that of the traditional production line. Smrobot 3000 design capacity 180 Double / hour, automatic precise spraying, not easy to overflow and lack of glue, good product rate of 99%, saving 30% of electric energy, using 40% glue consumables, reducing the rework rate of defective products and the loss of raw materials, greatly saving the production cost of shoe-making enterprises. According to different production lines, the same shoe type and flexible production line can be realized.

SMRobot3000 The series of technical indicators have reached the level of international first-class manufacturers and achieved domestic substitution. Machine replacement saves labor costs, so that shoe-making enterprise customers can recover the investment and expenditure of intelligent line in two years. To achieve high quality, high efficiency, high return, sustainable development of industrial prospects.

At the same time, the smart line adds a number of IOT IOT sensors to collect and analyze data. Combined with 5g intelligent manufacturing central control system, the intelligent line can centrally manage the production of the smart line and support mobile app Alarm, monitor production at any time. Make the operation deployment more simple, subvert the production process of traditional shoe production line, and realize the intelligent, modular and digital production process.

R & D innovation technology excellence

Deep insight Smrobot3000 series products are upgraded in hardware, software and manufacturing. The whole line is equipped with 6 sets of Shenzhen Huishi 3D industrial camera and 8 industrial robots realize the intellectualization and automation of shoe forming station. Using independent core R & D technology to configure 3D The intelligent vision track generation workstation can take high-precision 3D point cloud images of vamp and sole, and generate robot guided trajectory online in 5 seconds. It can realize automatic high-speed intelligent spraying of vamp, sole treatment agent, automatic sole pressing, automatic last pulling and automatic sulfur addition of vamp. According to the requirement of customer's production rhythm, add workstations freely.

Progress of industrialization promotion

At present, Shenzhen Huishi smrobot3000 We have reached in-depth cooperation with China's leading shoe-making enterprises, started to officially put into order production, and comprehensively promoted the intelligent production technology of shoe-making in the traditional shoe-making industry. It is committed to providing intelligent production and business environment for domestic shoe-making enterprises, guiding and promoting the popularization of intelligent shoe-making production line nationwide, and promoting the high-quality development of shoe-making industry.

- Related reading

Intelligent Production Line Of Shoe Making, Shenzhen Huishi Promotes The Upgrading Of Intelligent Manufacturing Industry With Machine Vision As The Core

|

Look At How Three Shoe Enterprises Go From Small Workshops To Information Chemical Plants.

|- Global Perspective | Global Perspective: Focus On European Nonwovens Industry Data

- Visual gluttonous | Nanamica Is The First To Preview The High Functional Environmental Protection Clothing Series In Autumn And Winter,

- Fashion Bulletin | Enjoy Cole Haan X Keith Haring'S New Ride

- Innovation and invention | Textile Fabric 3D Additive Printing Intelligent Equipment Project Passed The Scientific And Technological Achievements Appraisal Meeting

- Domestic data | Statistical Analysis Of China'S Fur Clothing Export Data From January To May

- Listed company | Shenzhen Textile A (000045): The Subsidiary Was Sued By 40% Shareholders And Demanded To Be Dissolved

- Daily headlines | Vigilance Against The Increasing Conspiracy Of US Intervention In Xinjiang Affairs

- Clothing store | Why Designer Brand By Far Plans To Open Stores In China

- Instant news | Ministry Of Industry And Information Technology And Other Six Departments Issued The Action Plan For Industrial Water Efficiency Improvement

- Instant news | Ministry Of Industry And Information Technology And Other Six Departments Issued The Action Plan For Industrial Water Efficiency Improvement

- Global Perspective: Focus On European Nonwovens Industry Data

- Nanamica Is The First To Preview The High Functional Environmental Protection Clothing Series In Autumn And Winter,

- Enjoy Cole Haan X Keith Haring'S New Ride

- Textile Fabric 3D Additive Printing Intelligent Equipment Project Passed The Scientific And Technological Achievements Appraisal Meeting

- Statistical Analysis Of China'S Fur Clothing Export Data From January To May

- Shenzhen Textile A (000045): The Subsidiary Was Sued By 40% Shareholders And Demanded To Be Dissolved

- Vigilance Against The Increasing Conspiracy Of US Intervention In Xinjiang Affairs

- Why Designer Brand By Far Plans To Open Stores In China

- Ministry Of Industry And Information Technology And Other Six Departments Issued The Action Plan For Industrial Water Efficiency Improvement

- Ministry Of Industry And Information Technology And Other Six Departments Issued The Action Plan For Industrial Water Efficiency Improvement